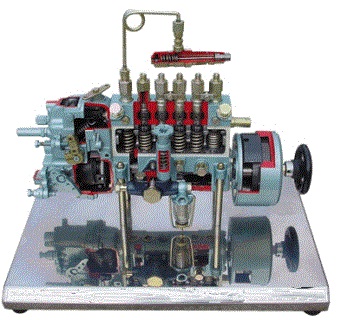

the Great Wall hover high pressure common rail diesel engine training platform

diesel engine architecture and working process.

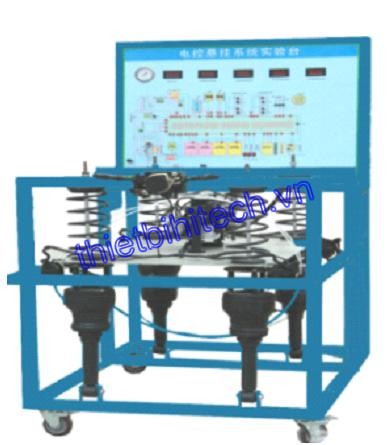

2.Training platform painted with a circuit diagram of the color inkjet, inkjet Figure is with plexiglass

protection, students can directly watch and compare circuit and engine object, understanding and

analysis of the control system working principle.

3.Training table panel installation testing terminals, can be directly on the panel detection sensor,

actuators, engine control unit pin electrical signals, such as F6resistance, voltage, current, frequency,

waveform signals.

4.Training table board installed in a car dashboard, can real - time display of engine speed, water

temperature, oil pressure light, charge indicator, electric control system fault indicator and other

parameters change.

5.Training platform installed with diagnosis block, can be connected with dedicated or universal auto

decoder, and can read the trouble code, clear trouble code, read data stream engine self- diagnostic

function to the engine electronic control system.

6.Equipped with patented technology, intelligent fault setting and assessment system: 1) Adopt digital

integrated circuit board, the latest MCU technology and supporting fault setting control technology,

with an exclusive patented technology, the system is stable, not easily infected. 2) Without a

computer can be an independent examination and assessment, teacher and student interface to

separate, the teacher via a password to enter the teacher interface questions, students answer in the

general interface. 3) With the test database compatible with the device, test database based on user

requests to edit. 4) High - definition of 0.225x0.225 point size of the LCD display, Chinese menu -driven

user interface, friendly man -machine dialogue. 5) Only four keys, simple and quick operation. 6) Can

be free to set the circuit breaker of any one circuit, short circuit, poor contact, failure phenomena; be

able to set and control module of the common failure of the foot. 7) According to the requirements of

equipment use adjust the quantity and type of fault set piont. 8) Install the RJ45 network interface,

equipped with RS- 232 serial port, can use cable and other equipment failures setting device to form a

network, set by the host computer to control each piece of equipment failures, troubleshooting,

parameter setting , remote start, feedback, assessment score.

7.With network- based intelligent fault diagnosis and assessment platform interface, butt joint with

network -based intelligent fault setting and assessment system

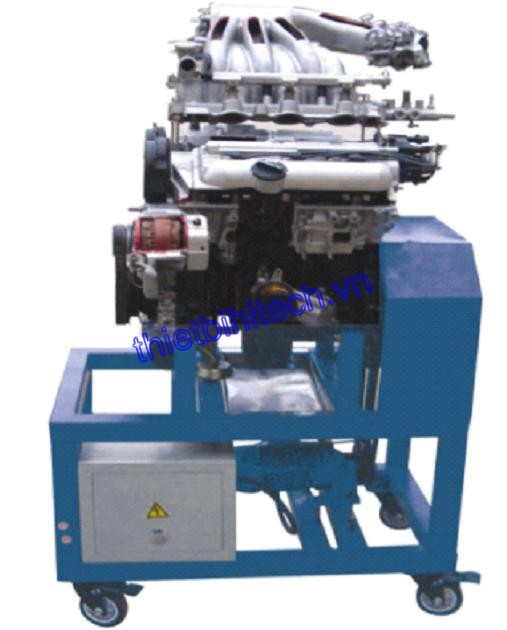

8.Training platform equipped with a power main switch, tank protection cover, flywheel shield, etc.

safety device.

9.Training base part uses the steel structure welding, surface uses the baking varnish craft process,

with self -locking castors device, move flexibly.