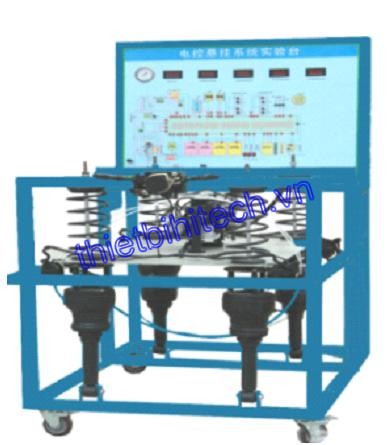

detection terminal, intelligent fault setting system, safety protection device, movable bench, operation

manual

â main parameters:

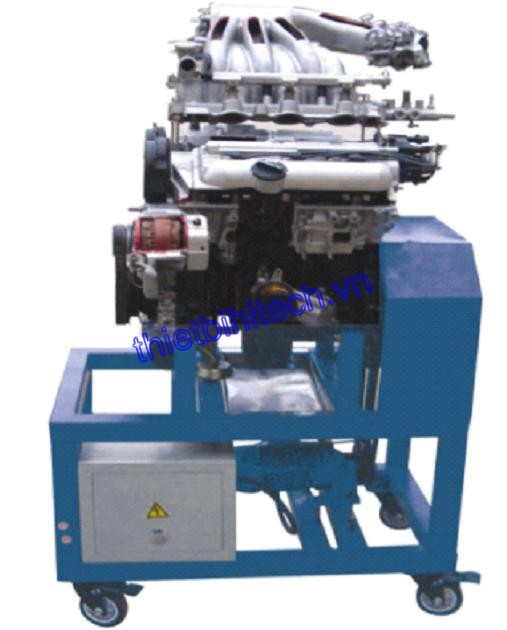

Engine type: straight four stroke eight valve electronic controlled gasoline engine

Displacement: 1.8L

Working voltage: 12V DC

Work environment: - 40 â- - 50 â

Size:1500*1000*2000mm

Weight:120Kg

â Main function

1, The dynamic operation function: based on Santana 2000AJR engine assembly, equipped with the

auxiliary control system, sensor and actuator, make sure the normal operation of an engine, dynamic

demonstrate the working process.

2, The display function: through the original vehicle wiring harness connection combination

instrument, vacuum pressure gauge, fuel pressure gauge and so on, can be real - time display the

various state dynamic, static signal parameters during engine operation.

3, Detection functions: external detecting terminal are installed on the training platform panels, can

be directly on the panel detection sensor, actuator, the engine control unit pin electrical signals, such

as resistance, voltage, frequency, waveform signal.

4, Signal simulation function: can do signal simulation for each engine electronic control system

sensor, and the real -time detect the change of running state of engine caused by the sensor input

signal changes.

5, Self diagnostic function: equipped with computer data detection port, can be connected with

special or general decoding apparatus, do ECU code query, read the fault code, clear fault code,

read data stream, waveform analysis, actuator test self diagnosis function to the engine electronic

control system.

6, Fault setting function: equipped with intelligent fault setting and assessment system, and with a

device is adapted to the test questions library, examination questions library based on user demand

for editing, can set a variety of common faults related to module pin . Installation of RJ45 network

interface, equipment with serial RS- 232, can use cable and other equipment fault setting device

compose a network, by the main control computer controls each of the equipment fault settings,

troubleshooting, parameter setting, remote start, information feedback, assessment score and other

functions.