Jetta diesel engine training platform

â Product Overview

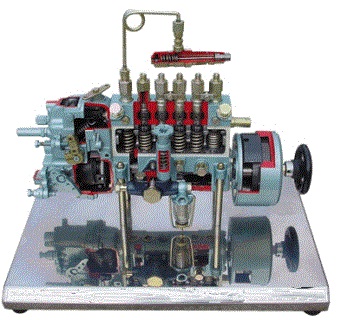

Engine assembly and control unit, the original vehicle wiring harness, instrument cluster, various

sensors and actuators, the diesel tank and diesel pump assembly, batteries, digital voltmeter,

vacuum gauge, fuel gauge, ignition switch, heat sink, color panel of the circuit schematic, external

testing terminal, intelligent fault setting system, safety devices, mobile stand, manual, etc..

â main parameters:

Engine Type: inline four- cylinder four-stroke EFI diesel engines Displacement: 1.9L Operating

voltage: 12V DC Working environment: - 40 â ~ 50 â

Size:1900mm × 1200mm × 1400mm

Weight:100Kg

â Main function

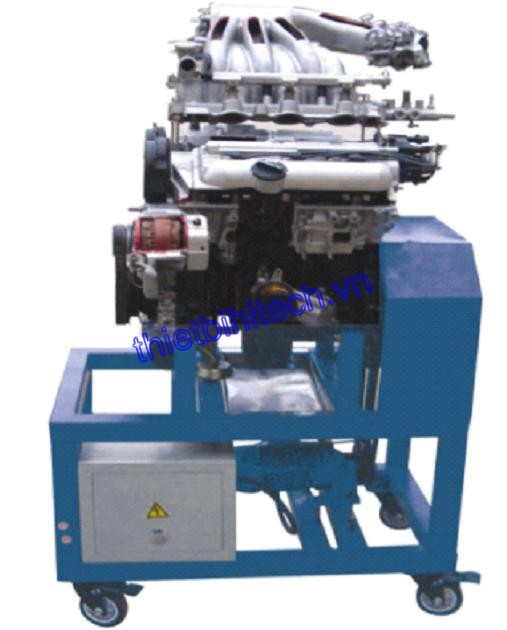

1.Dynamic operating functions: The Jetta 1.9SDI electronically controlled diesel engines assembly as

basis, with the auxiliary control system, sensors and actuators to make the normal operation of the

engine, dynamic presentations of their work process.

2.Display functions: Through the original car wiring harness to connect the combination meter, can

be real - time display engine operation during the various state dynamic, static signal parameters.

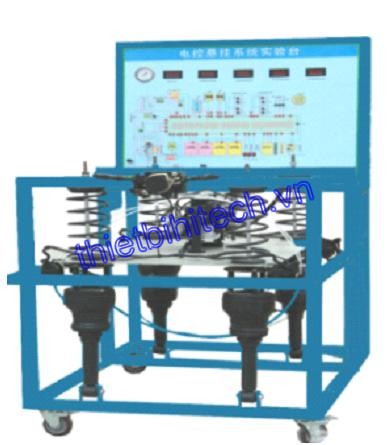

3.Detection: Training table board to install an external detection terminals, can be directly on the

panel detection of sensor, the pins of the electrical signals of the actuators, engine control unit, such

as resistance, voltage, current, frequency, waveform signals.

4.Signal simulation capabilities: Signal simulation to the engine electronic control system sensor, and

real - time detection engine running state changes caused by changes in the sensor input signal.

5.Self -diagnostic function: Equipped with computer data detection port, can be connected with

dedicated or universal decoding apparatus, and can do coding queries, read trouble code, clear

trouble code, read data stream, waveform analysis, the implementation of component testing from

diagnostic capabilities to the engine electronic control system ECU.

6.Fault setting function: Equipped with intelligent fault setting and assessment system, with a test

database compatible with the device, test database can be edited according to user needs, be able to

set and control module of the common failure of the foot. Installed with RJ45 network interface,

equipped with RS- 232 serial port, can use the cable and other equipment failure set the device to

form a network, set by the host computer to control each piece of equipment failures,

troubleshooting, parameter setting, remote start, feedback, assessment score